Tracing stock throughout the warehouse can be a confusing and time-consuming task, particularly if it has to be done manually. Having the capability to monitor inventory using barcodes and intelligent software designed to make these processes simpler, will help improve efficiency and streamline processes within the warehouse.

What is serial/batch tracking?

Serial or batch tracking is a method of monitoring stock throughout the warehouse by assigning serial, batch or lot numbers against items. These numbers can then be used to search for the locations of specific products within the warehouse.

How does serial/batch tracking work in Bit Inventory 50?

Bit Inventory 50 has been designed to make inventory management a much more accurate and efficient process through its integration with Sage 50.

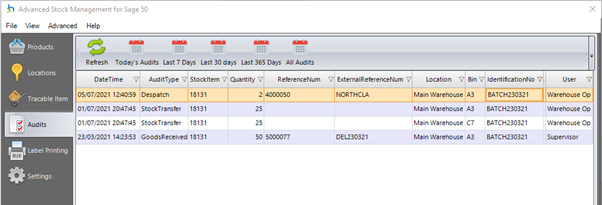

Serial/batch tracking works in Bit Inventory 50 by having specific numbers assigned against products. When a product is placed in a certain location within the warehouse, this information gets inputted into the Bit Inventory 50 software. When a specific product code is then searched, the location it has been referenced in will be brought up, along with the locations it has previously been placed, giving a full view of that products journey through the warehouse.

The Bit Inventory 50 software allows for items to be more easily monitored and found, saving warehouse staff valuable time when picking customer orders. This allows businesses using the software to meet customer needs more efficiently, leading to an increased capacity within the warehouse. Bit Inventory 50 is also GS1 compliant, holding all the necessary data for pharmaceutical products within one barcode.

Summary

Serial/batch tracking in Bit Inventory 50 is a simple process of monitoring specific products on their journey through the warehouse, making sure they’re placed in the correct locations ready for picking customer orders. A full history of an item’s journey through the warehouse can also be seen, which can be useful, for example, if a perishable good had been stored in the wrong location and has therefore spoiled.

For more information about how Bit Inventory 50 can help streamline your warehouse processes, contact us today.